Development of GEM PVD Coatings

Development of GEM PVD Coatings :

2000 - 2013

The Mono-block and Multi-layer coatings:

- Include adhesion layer

- Thickness: 1-10 µm

- Include TiN(CN),(Ti,Al)N(CN),CrN(CN), (Cr,Al)N(CN),TiSiN(CN), (Ti,Al,Si)N,(Cr,Al,Si)N(CN)

- Hardness: up to 38 Gpa

- Adhesion level: HF1

- Roughness(Ra): 0.1-0.5 µm

- General application

2000 - 2013

2013 - 2020

2013 - 2020

After 2020

After 2020

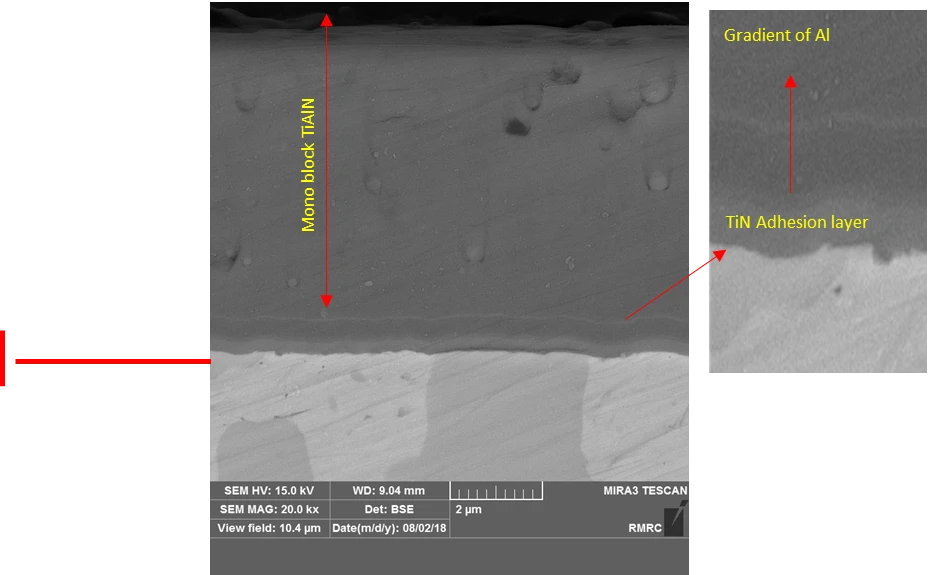

2000-2013

The Mono-block and Multi-layer coatings:

- Include adhesion layer

- Thickness: 1-10 µm

- Include TiN(CN),(Ti,Al)N(CN),CrN(CN), (Cr,Al)N(CN),TiSiN(CN), (Ti,Al,Si)N,(Cr,Al,Si)N(CN)

- Hardness: up to 38 Gpa

- Adhesion level: HF1

- Roughness(Ra): 0.1-0.5 µm

- General application

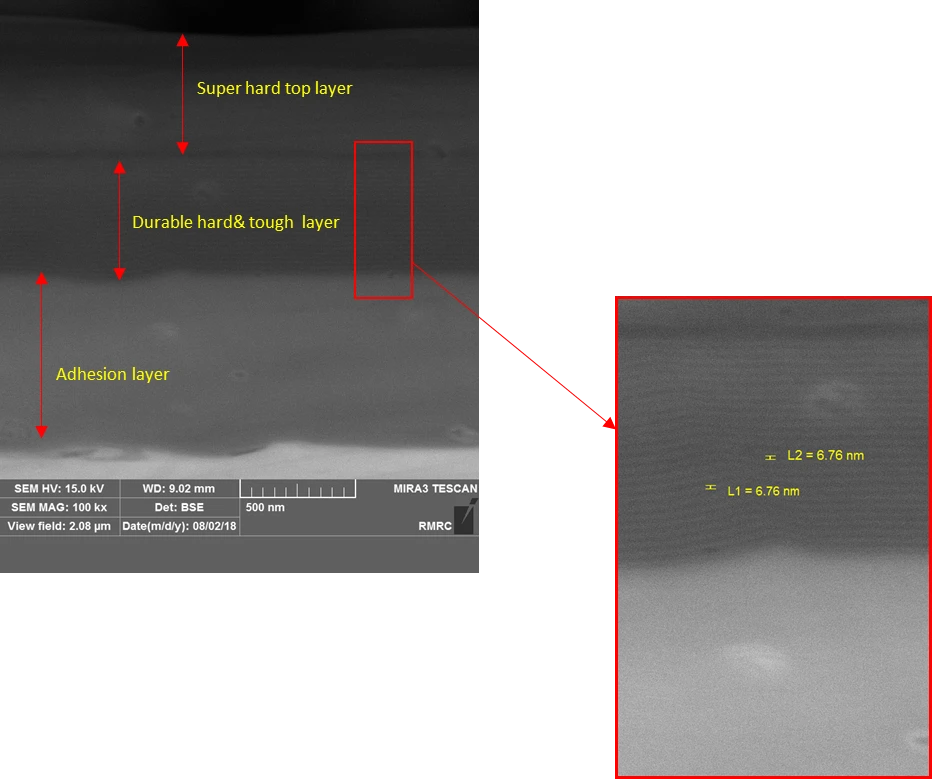

2013-2020

The best durable super hard coatings in triple & quad structure which designed according to the working condition:

- Smooth & super hard top layer

- TiN, TiCrN, CrN adhesion layer

- Enhanced hardness & toughness by multi Nano layer & nanocomposite structure

- Flexible application according to global standards

NEW COTINGS

Benefits

- friction coefficient(≤0.05)

- Hardness(≥30 Gpa)

- roughness(Ra≤0.1µm)

- High corrosion resistance

- Multy function

- Economical