Evaluation of Coatings

Evaluation of GEM PVD Coatings

Coating Advantages:

- Improvement of surface sticking

- Improvement of surface hardness (up to max: 5000HV)

- Improvement of erosion resistance

- Decrease of friction coefficient (min: 0.05)

- Increase of temperature resistance (up to 1200°C)

- Improvement of surface roughness (up to Ra: 0.05)

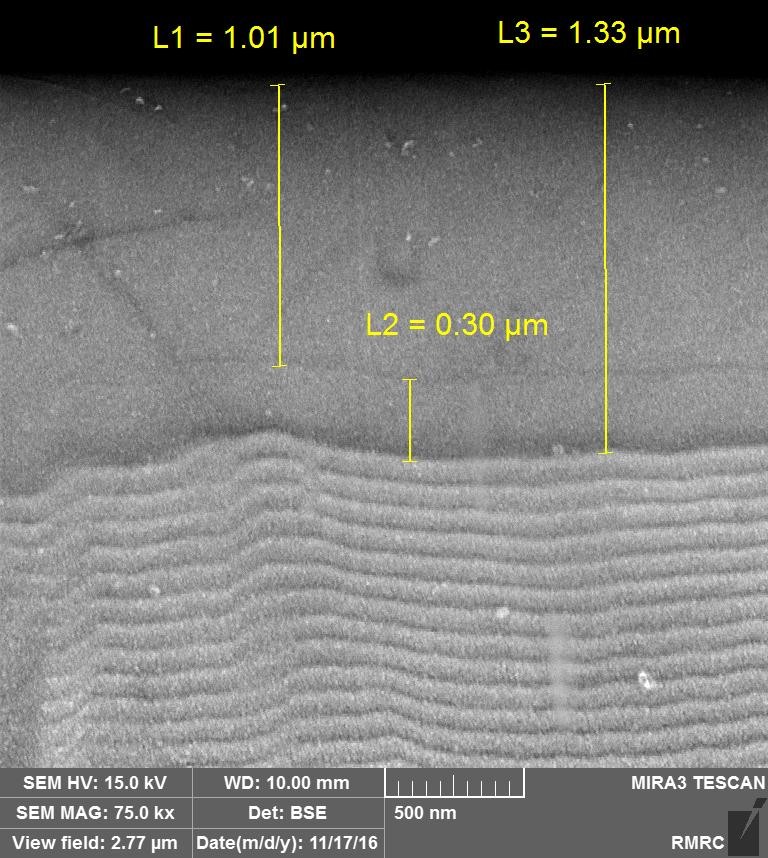

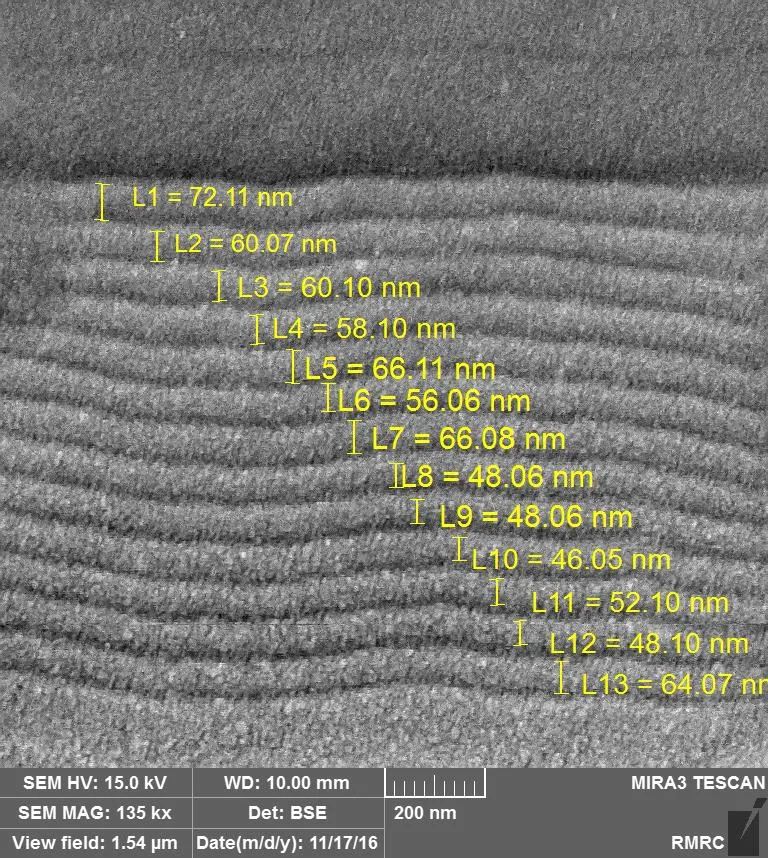

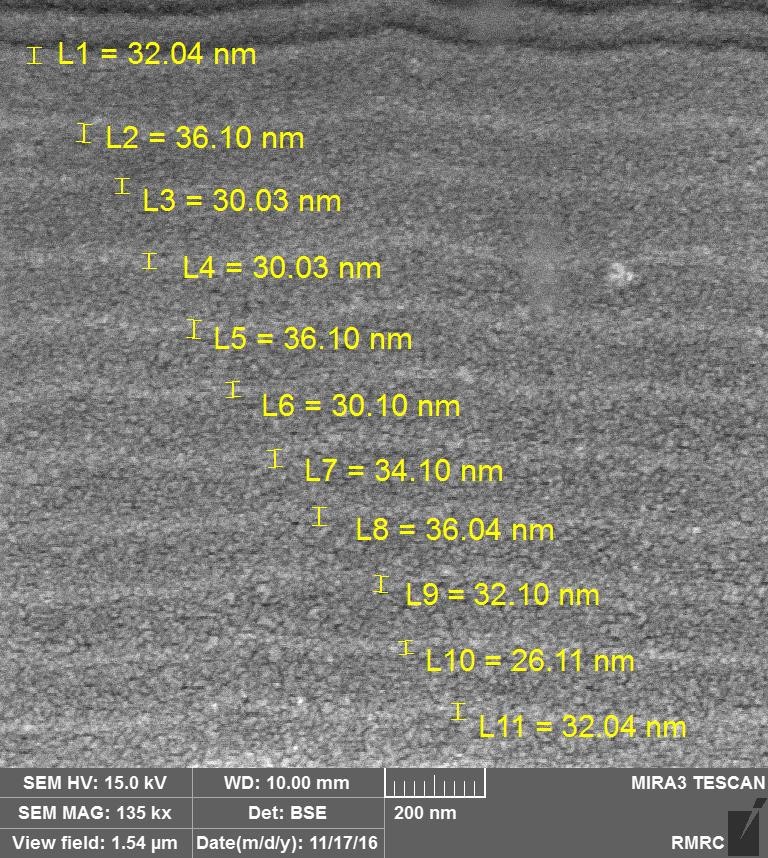

Architecture of GEM coatings

Quad nanostructure

- Substrate: HSS-8%Co

- Part “D” :TiN adhesion layer

- Part “C” :TiN-CrN hard&tough durable layer

- Part “B” :TiN-TiAlN hard&tough durable layer

- Part “A” :TiSiCN super hard top layer

- Temp. resistance:800 ⁰C

- Total thickness:4 microns

- Roughness(Ra):0.15 µm

- Total hardness:34 GPa

- Excellent wear resistance

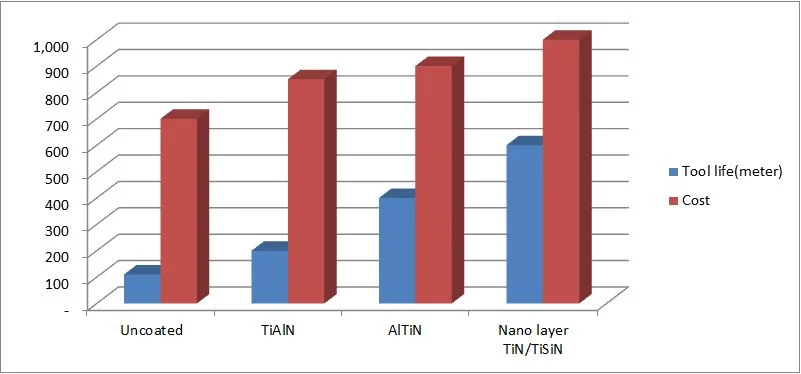

GEM Nano-Coating Evaluation in major industrial applications:

1-High speed round cutting tools include: Drills, Taps, Reamers, End mills, saws

The coating type is depends on the kind of work piece. Tool life increase 2-5 times more (depend on coating type, application condition and substrate type)

Substrate: SAW

Precision cutting of 3 mm profiles, Cast Iron

Tool: carbide circular saw blade ɸ 100mm x 0,8mm, z=200

Cutting conditions: n=400 rev/min, vf=64 mm/min, lubrication: oil

Source: Iran industrial valves/Isfahan/Iran

Substrate: End mill

Work piece material: X40CrMoV5 – 1.2344 – R =1100 N/mm²

Tools: d=12mm – solid carbide end mill with corner radius r=2mm

v = 218 m/min – f=0.26mm – a =0.5mm – a =8mm – emulsion 7%

Source: Abzar sanat co./Tehran/Iran

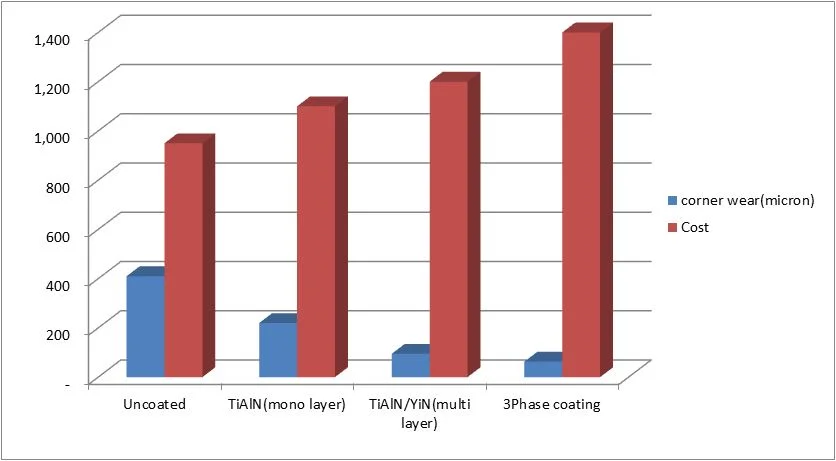

Substrate: Drill

Material: 42CrMo4 – IC-p=40 bar – emulsion 5% –

Comparison after L =50m drilling distance

Tools: solid carbide drills – d=12mm a =5xd-v=120 m/min-f=0.35 mm/rev

Source: Vamco co./Tehran/ Iran

2-Punching and deep drawing and forming dies:

The coating type is depend on application condition and substrate type. Tool life increase 2-20 times more

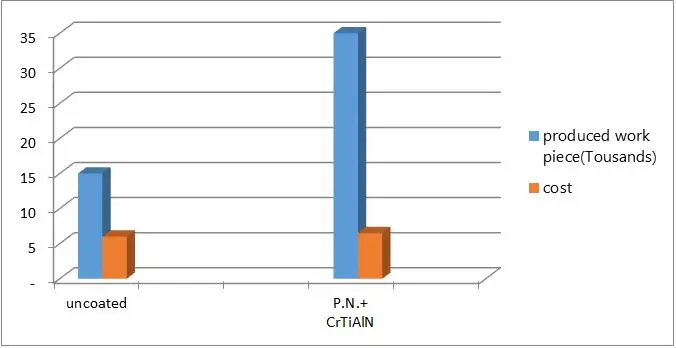

Substrate: Punch

Punch material: Hss-8%Co, Hardness: 64 HRC

Work piece material: INOX 0.8 mm;

Source: Poolad tarash Iran co./Isfahan/Iran

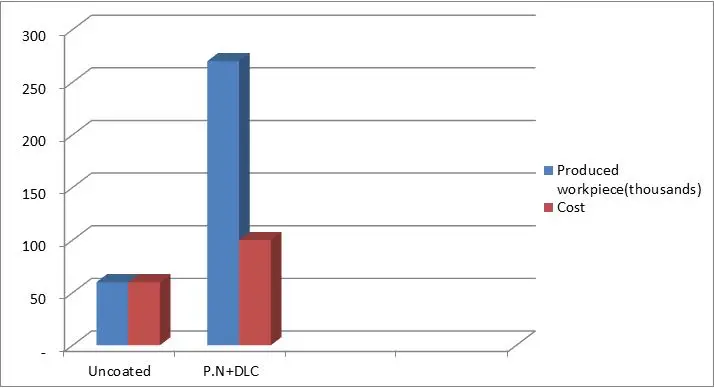

Substrate: Deep drawing Die

Material of die: 1.2379,58 HRC

P.N Thickness: 150micron,

Work piece material: ck45

Source: Part Lastic co./Mashhad/Iran

3-Hob & shaper gear cutter:

The coating type is depend on speed of cutting and work piece material) Tool life increase 5-30 times more (more tool life increase for re-sharpened tools)

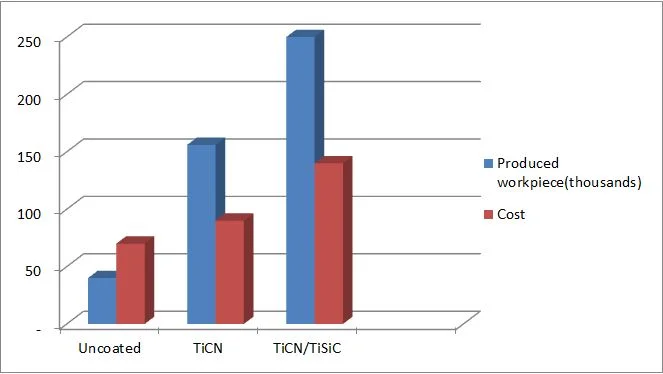

Substrate: Gear SHAPER

– Steel 27MnCr5 (270HB), Modulus2

– Substrate: S290 (1010HV10)

Cutting conditions: Vc = 140 m/min,

Hmax=0.3mm, dry, down Shaping

Source: Niroo Mohareke co./Ghazvin/Iran

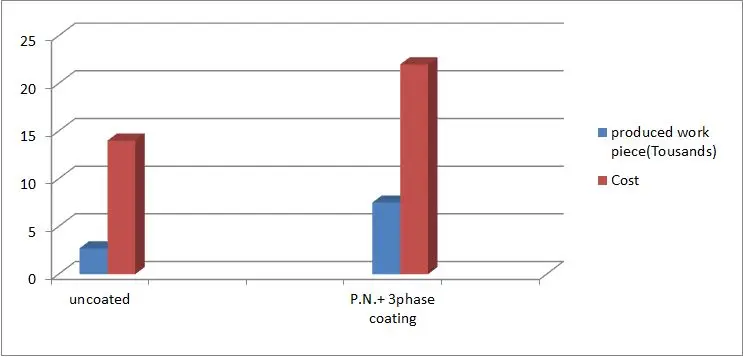

4-Die casting

The coating cause: more delay for thin cracks, no sticking of aluminum to die, Better temperature resistance of die, low coat work piece production. Working time until failure (days)

Substrate: Die casting Pins

Substrate material: 1.2344, 48HRC

P.N. Thickness: 100Micron

PVD Thickness: 5Micron

Source: Iran Khodro casting co./Abhar/Iran

5-Hot forging of brass

Substrate: Hot forging Die

Die material: 1.2344, 48HRC

Work piece temperature: 760°C

P.N, Thickness: 100 micron, PVD Thickness: 7micron

Source: Azaran co./Isfahan/Iran

6-Hot forging of steel

Substrate: Hot forging Die

Die material: 1.2344, 48HRC

Work piece temperature: 1100°C, Press force: 1100 tons

P.N, Thickness: 150 Micron, PVD Thickness: 7 micron

Source: Mashhad forging co./Mashhad/Iran