Products

Advanced hard coating by JHDI-Q4 MACHINES

NanoComposite + DLC

General Information

- Hard coating + DLC (metal doped diamond like carbon ) Unit.

- Based on GEM nanocoating technology (4th generation )

- Coating on tool steels and high speed steels (HSS) between 250 - 400 °C and on tungsten carbide (WC) between 300 - 450 °

Hard Coatings

- Monolayers, Multilayers Nanolayers, Nanocomposites, and their combinations.

- Main standard coatings.

Hardware

- Max. Foot print: W4500 x D5500 x H2500 mm

- Diffusion pump High vacuum system

-

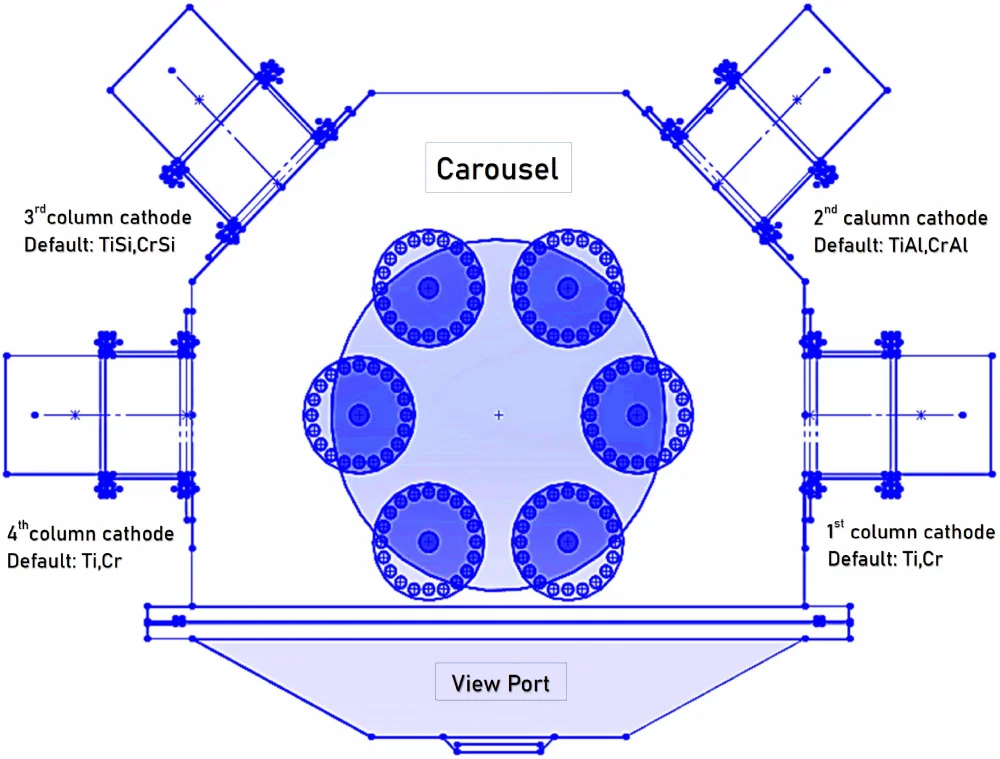

New advanced GEM planar cathode.

target size: Ø90 mm Hidden trigger system Adjustable cathode during coating stainless steel, water cooled chamber and cathodes Easy cathode service after coating - GEM shutter

- Ar Glow Discharge

- Ionic plasma cleaning:

- metal ion etching (Ti, Cr)

- Pulsed BIAS supply (20 kHz),max 700V,30A

- Air conditioning for the electric cabinet

- Up to3gas channels, 3 MFC controlled

- dust shield for heaters

- Electrical connection: 3x400V, 120A external fuse 50-60 Hz, max.70 kVA

- Chamber preheating

- Changeable chamber shields

- Pulsed ARC supplies with low frequency

Electronics and Software

- Control system with touch-screen menu driven concept

- No programming knowledge is required for control

- Data logging and real-time viewing of process parameters

- Insite operator's manual

Max. Optimal Cycle Times(full chamber)

- Vacuuming, Substrate heating, plasma etching : 120 min

- Coating : 2micrometer/hr

- Cooling :60 min

Available in 4 sizes

- X-Large chamber

- Large size chamber

- Medium size chamber

- Small size chamber

X-Large chamber

- Internal chamber size: Diameters 1100*1500 mm

- Usable plasma volume: Diameters 800*1400 mm

- Uniform Coating area(±0.2μm): Diameters 700*1300 mm

- Maximum load: 1500 Kg

- 16 “04series” Arc cathodes: 4columns-4rows

- Target size: Diameter 90 mm

- OPTIONAL: Available for coating broaches up to 1500 mmModel

Large size chamber

- Internal chamber size: Diameters 1100*1200 mm

- Usable plasma volume: Diameters 800*1100 mm

- Uniform Coating area(±0.2μm): Diameters 700*1000 mm

- Maximum load: 1200 Kg

- 12 “04series” Arc cathodes: 4columns-3rows

- Target size: Diameter 90mm

Medium size chamber

- Internal chamber size: Diameters 1100*1000 mm

- Usable plasma volume: Diameters 800*900 mm

- Uniform Coating area(±0.2μm): Diameters 700*800 mm

- Maximum load: 800 Kg

- 8 “04series” Arc cathodes: 4 columns-2 rows

- Target size: Diameter 90 mm

Small size chamber

- Internal chamber size: Diameters 1100*800 mm

- Usable plasma volume: Diameters 800*600 mm

- Uniform Coating area(±0.2μm): Diameters 700*500 mm

- Maximum load: 600 Kg

- 4 “04series” Arc cathodes: 4 columns-1 rows

- Target size: Diameter 90 mm

Special options:

- Two months training by Gem Nano coating authors in your factory

- One year guarantee in all parts

- Providing Extra parts for one year “O” rings, oils, heaters, chamber covers and etc

- Technology transferring for pre & post treatment on different industrial parts

- Easy operation to reach every kind of architectural coatings

Schematic of chamber design and cathodes arrangement

Schematic of Jigs and Fixtures for cutting tools coating

Inside the Carousel